Our Other Products

- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE

Our Products

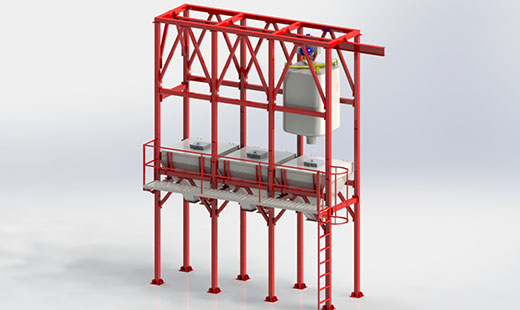

BIG BAG UNLOADING STATION

- DESCRIPTION

- TECHNICAL FEATURES

- PRODUCT VIDEOS

Advantages

- Safe Working Environment

- Dust-free Ambient

- Easy to load

- Adaptable to different conveyor and storage systems

- Wide selection of models for different big bag sizes

- Easy to clean

- Maintenance-free structure

Working system

Big bag, is placed in its place with big boys own crane mechanism or by a user with a forklift truck. Discharge nozzle is opened. The big bag is discharged by operating the pneumatic conveying or auger system from the control panel.

Our Other Products

- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE