- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE

- DESCRIPTION

- TECHNICAL FEATURES

- PRODUCT VIDEOS

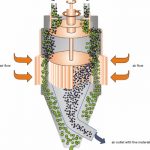

DCS belongs to the family of air flow turboplex classifiers, also called centrifugal classifiers. These classifiers achieve very high efficiency at a low specific energy consumption. It is a robust design of EGEAY.

OPERATING PRINCIPLE

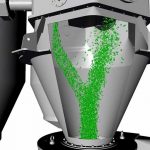

After entering the machine, classifier air flows in the centripetal direction through the classification rotor. In the process, classifying wheel extracts fine particles from feed material and transfers them to fine discharge cavity. Rough materials which are denied by classifying rotor are slope downwards. The air routing shown schematically is very simplified because before the coarse material exits the classifier, it is again rinsed with air to remove any remaining particles. This results in an extremely clean coarse fraction.

Product is either fed through a rotary valve or by an air flow classifier entering the classification air. Product fineness is controlled by adjusting the classifier wheel speed using a frequency converter. The horizontal operation of the classifying wheel means that even "difficult" products can be processed smoothly.

Air flow turbo classifiers, can be coated with ceramic. The body can be ceramic coated to prevent abrasive materials from damaging the machine body.

FEATURES

- Air classifiers with single or many rotors for extremely fine classification

- 5 to 10 µm in fine-grained powders; with the DCS-ES model, a precision of = 2 µm (= 0.3 µm) is possible.

- Smooth operation in all product classifications

- High wear resistance

TURBOPLEX DCS MULTI-ROTOR CLASSIFIER

ADVANTAGES

There is no other type of classifier so well adapted to the demands of practical work as the Turboplex ultrafine classifier:

- Basic and reliable design lowers the cost of maintenance and service.

- Sharp upper size limitation

- The horizontal operation of the grading rotor helps to prevent wear even when working with abrasive products.

- For abrasive products: Ceramic rotor and ceramic coating / polyurethane lining

- Ultra-high fineness values.

- Stable operation even if the feed rate fluctuates.

- Modest space requirement.

- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE