- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE

- DESCRIPTION

- TECHNICAL FEATURES

- PRODUCT VIDEOS

MIXING UNITS

EGEAY with its technology which developed in many years in Horizontal Powder Mixers which are lifeline of many facilities helps it customers to produce fine mixed products.

Every single part that make up the mixer are products of a vast experience and working. With its upgraded bedding, mixing compartments with high protection against abrasion, product inlet and outlet units, main body, drive system it will serve you for many years. In addition, turbo shredder, automatic sampling apparatus, hydraulic clutch options are also available for your service.

Capacity (Lt) | Body Diameter (Ø D mm) | Body Length (mm) |

1400 | 1090 | 1600 |

2000 | 1220 | 1800 |

2500 | 1220 | 2200 |

3000 | 1220 | 2650 |

3000 | 1320 | 2300 |

3000 | 1420 | 2650 |

4000 | 1420 | 2600 |

To achieve a homogenous mixture in Horizontal Powder Mixers quickly, mixing angles of mixer blades plays a major role. Our company, which is a leader in its sector, has designed the wing by considering the environmental speed and material structure.

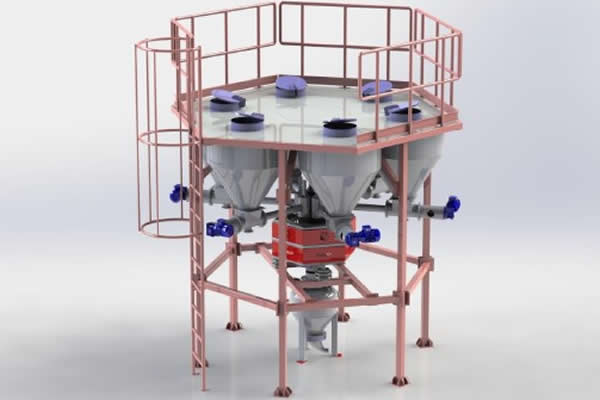

DOSING UNITS

In general the process of adding additives to the original raw material is called dosing. This setting can be measured by highly sensitive devices and is a great importance to the mixing quality.

EGEAY dosing systems are designed to effortlessly send the raw materials and chemicals that need to be dosed during a recipe process to the right area by weighing the right amount without the employee's initiative, we aim to completely eliminate the errors caused by the employee and to ensure standardisation in your recipes.

EGEAY dosing systems automatically transport and measure the desired raw material from the raw material silos and bunkers or stock tanks to the weighing chamber by means of auger, conveyor belt.

The equipment used in the systems will be designed to be compatible with all raw materials and chemicals to be used in your sector. In case of using chemicals with special conditions, the structure and fluidity of the chemical, its corrosive-abrasive effects are examined, and the equipment suitable for your chemical or main raw material is selected.

According to the recipes received from our customers operating in the food, chemical, plastic or construction chemicals sectors, the number of silos or raw material bunkers is determined, the raw material transfer method to be used between the raw material silo or bunker and the weighing bunker is determined according to the characteristics of the raw material, belt, screw or pneumatic, then the volume of the weighing bunker is determined according to the mixer where the mixture will be made. In general, smaller volume weighing hoppers are used for chemicals with low usage rate in the recipe or for chemicals that need to be weighed with high precision, and larger volume weighing hoppers are used for main raw materials with high usage rate, we can express this briefly as micro and macro dosing.

MIXING UNITS

EGEAY with its technology which developed in many years in Horizontal Powder Mixers which are lifeline of many facilities helps it customers to produce fine mixed products.

Every single part that make up the mixer are products of a vast experience and working. With its upgraded bedding, mixing compartments with high protection against abrasion, product inlet and outlet units, main body, drive system it will serve you for many years. In addition, turbo shredder, automatic sampling apparatus, hydraulic clutch options are also available for your service.

Capacity (Lt) | Body Diameter (Ø D mm) | Body Length (mm) |

1400 | 1090 | 1600 |

2000 | 1220 | 1800 |

2500 | 1220 | 2200 |

3000 | 1220 | 2650 |

3000 | 1320 | 2300 |

3000 | 1420 | 2650 |

4000 | 1420 | 2600 |

To achieve a homogenous mixture in Horizontal Powder Mixers quickly, mixing angles of mixer blades plays a major role. Our company, which is a leader in its sector, has designed the wing by considering the environmental speed and material structure.

DOSING UNITS

In general the process of adding additives to the original raw material is called dosing. This setting can be measured by highly sensitive devices and is a great importance to the mixing quality.

EGEAY dosing systems are designed to effortlessly send the raw materials and chemicals that need to be dosed during a recipe process to the right area by weighing the right amount without the employee's initiative, we aim to completely eliminate the errors caused by the employee and to ensure standardisation in your recipes.

EGEAY dosing systems automatically transport and measure the desired raw material from the raw material silos and bunkers or stock tanks to the weighing chamber by means of auger, conveyor belt.

The equipment used in the systems will be designed to be compatible with all raw materials and chemicals to be used in your sector. In case of using chemicals with special conditions, the structure and fluidity of the chemical, its corrosive-abrasive effects are examined, and the equipment suitable for your chemical or main raw material is selected.

According to the recipes received from our customers operating in the food, chemical, plastic or construction chemicals sectors, the number of silos or raw material bunkers is determined, the raw material transfer method to be used between the raw material silo or bunker and the weighing bunker is determined according to the characteristics of the raw material, belt, screw or pneumatic, then the volume of the weighing bunker is determined according to the mixer where the mixture will be made. In general, smaller volume weighing hoppers are used for chemicals with low usage rate in the recipe or for chemicals that need to be weighed with high precision, and larger volume weighing hoppers are used for main raw materials with high usage rate, we can express this briefly as micro and macro dosing.

- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE