- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE

- DESCRIPTION

- TECHNICAL FEATURES

- PRODUCT VIDEOS

EGEAY Machinery with its vast experience and knowledge in results of long years of having served in the machinery and mining machinery sector establishes facilities with the latest technology systems by creating a system according to appropriate working conditions. Our company according to customer demands desired process and given capacity makes turnkey plant installations by designing the plant. It establishes "Natural Calcite" and "Coated Calcite" plants according to the needs of the sector. Most important features in our facilities that we manufacture are low cost of operation and their longevity. . EGEAY Machinery provides a satisfactory customer service with fast and short time solutions without discriminating between domestic and international customers. By choosing us again and again our customers is the sole proof of our service. Call us, and let us make the best machines for your needs and capacity with our vast experience.

OPERATING PRINCIPLE

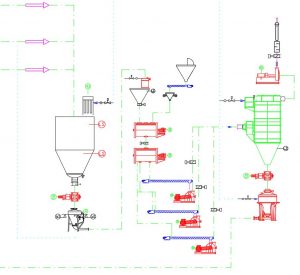

Calcite sized in the micronizing facility, is stocked in coating product silo. The stocked calcite is weighed in the weighing hopper and sent into the mixer. At the same time, stearic acid is weighed in the stearic acid weighing hopper and sent into the mixer. The product mixed in the mixer is fed to the raymonds and after the process there, the material absorbed through the jet pulse filter goes to the packaging machines under the filter and the packaging process is carried out.

Calcite Micronizing Plant Flow Diagram

- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE