- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE

- DESCRIPTION

- TECHNICAL FEATURES

- PRODUCT VIDEOS

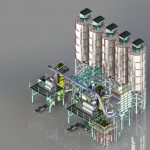

As EGEAY MAKİNA, we are establishing a fully automated, fully automatic PLC controlled turnkey plant for the production of materials such as Gypsum and Cement or ceramic adhesives, joint fillers, surface hardeners. We also manufacture machinery and electrical equipment to be used in line with the special requests of our customers.

Construction chemicals plants with a capacity of 20-50 tonnes per hour are fully automated plants. In general, mixers with a product mixing capacity of 2,500 - 4,000 litres are suitable. However, larger or smaller mixers can also be used according to the need. The plant is usually operated as double line. Gypsum and cement based production can be made.

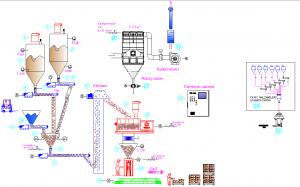

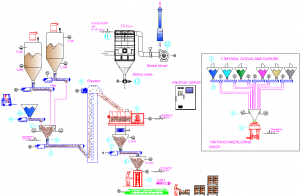

1-Vertical Plant:

In this plant, raw material silos are at the top side of the steel structure and there is one silo for each of raw material. Raw material flow is done from higher to lower.

Packaging Floor (Ground Floor) / Mixing Floor (First Floor) / Dosing and Farming Floor (Second Floor) / Raw Material Storage Floor (Third Floor)

2-Pneumatic Transfer Supported Plant:

Different from vertical plant, the silos are on the ground level. Product transfer is done by the support of pneumatic conveying.

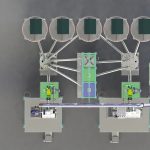

CONSTRUCTION CHEMICALS PLANT FLOW DIAGRAM

MAIN MACHINES

- Pneumatic conveyor

- Silo and accessories

- Dosing and Weighing bunker

- Manual feed bunker and auger

- Bucket Elevator

- Mixer

- Platform

- Packaging upper bunker

- Packaging machine

- Bag outlet conveyor and accessories

- Jet-Puls filter and installation

- Automatic Packaging line

- Automatic pallet stretching line (Stretch Hood)

- Electricity Panel

- Scada automation system

- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE