- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE

- DESCRIPTION

- TECHNICAL FEATURES

- PRODUCT VIDEOS

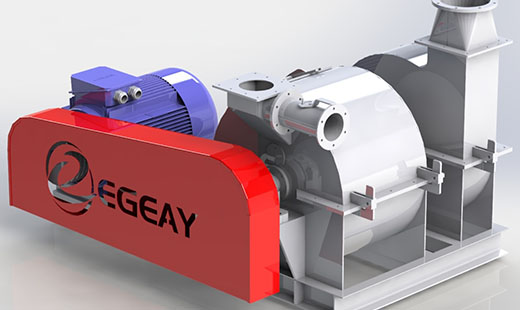

With EGEAY Machinery product Raymond, it will be possible to coat micronized industrial materials (Quartz, Feldspar, Talc, Calcite, Gypsum, Limestone, Dolomite and other) easily and in the best way.

EGEAY Machinery, which has manufactured and commissioned dozens of Raymond mills since its establishment, is always ready to establish reliable and efficient coating systems for you.

Call us, and let us make the best machines for your needs and capacity with our vast experience.

OPERATING PRINCIPLE

Raymond, whose installation is completed, is fed with the product coming from our coating mixers through an auger. Thanks to the special manganese armours on the Raymond body and the St52 heat treated hammers connected to the rotor, the material is frictioned and heated at a certain rate, thanks to this heating, the stearic acid in the product coming from the mixer is heated and coated around the product to be coated.

Raymond, whose installation is completed, is fed with the product coming from our coating mixers through an auger. Thanks to the special manganese armours on the Raymond body and the St52 heat treated hammers connected to the rotor, the material is frictioned and heated at a certain rate, thanks to this heating, the stearic acid in the product coming from the mixer is heated and coated around the product to be coated.

FEATURES

- Extremely reliable design

- Low specific energy consumption

- Low investment cost

- Quick and easy maintenance resulting from low cost of maintenance

- For abrasive products: The body is made of manganese cast iron armour plating, the hammers are made of heat hardened St52 material.

- High Durability Body

- Easy hammer replacement

- There are high-tech heat and flap sensors at the required points.

ADVANTAGES

Our Raymond machines are designed for high performance at low energy consumption

- Basic and reliable design lowers the cost of maintenance and service.

- It ensures the most efficient coating of the material to be coated.

- In the products taken from our Raymond machine, cleaner and trouble-free results are obtained in the application areas.

- Low cost of investment

- Stable operation even if the feed rate fluctuates

- Modest space requirement.

- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE